Topic Content:

- Processing of Plastics

Some methods of production of plastic include:

- Injection molding

- Compression molding

- Extrusion molding

- Calendering

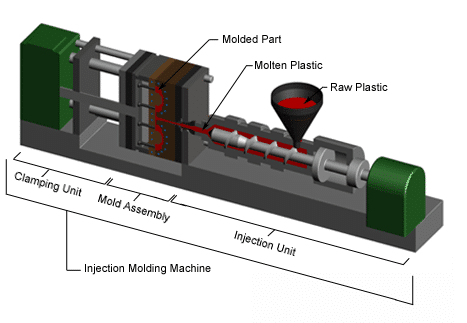

Injection Molding:

The most commonly used manufacturing process for the fabrication of plastic parts is injection molding. A wide variety of products are manufactured using injection molding. The injection molding process requires the use of raw plastic material, a mold, and an injection molding machine. The plastic is melted in the injection molding machine and then injected into the mold, where it cools and solidifies into the final part.

You are viewing an excerpt of this Topic. Subscribe Now to get Full Access to ALL this Subject's Topics and Quizzes for this Term!

Click on the button "Subscribe Now" below for Full Access!

Subscribe Now

Note: If you have Already Subscribed and you are seeing this message, it means you are logged out. Please Log In using the Login Button Below to Carry on Studying!

Responses